Fermentation Powers Biopharma…and Breweries

- Posted by Brian Kennedy

- On November 21, 2017

The fermentation process used in beer brewing is similar to the process used in the biopharmaceutical industry to produce therapeutic molecules. To see fermentation up close and personal, make sure you register for the November 30th brewery tour and networking social at Lord Hobo Brewery in Woburn.

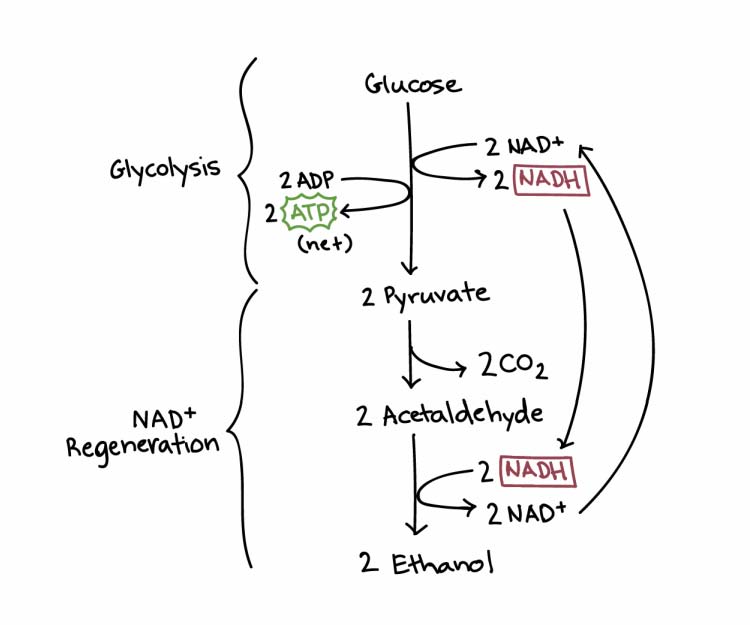

In a few words, fermentation is the process by which microorganisms, typically yeast or bacteria, convert sugars to energy in the form of ATP. This conversion usually happens in the absence of oxygen, or in oxygen-poor media, and the byproducts of this particular type of cellular metabolism include ethanol, CO2, and lactate.

In industry, the term “fermentation” is often used generally to describe any microbial process, with or without oxygen used to manufacture a commercial product, namely a useful metabolite or recombinant protein. Some common examples of this in the pharmaceutical industry are the production of insulin (a hormone that regulates the absorption of glucose into our cells) and antibiotics such as penicillin and ampicillin.

A cell line is chosen and engineered based on the characteristics of the desired end result. Bacterial expression systems may be selected when the product is a relatively simple protein that does not require extensive post-translational modifications (as is the case with insulin), or a metabolite that is natively produced at high quantities. A eukaryotic expression system like mammalian cells may be selected when the product is a more complex protein or if the organism has a high metabolic flux towards the chemical of interest, requiring less strenuous engineering efforts.

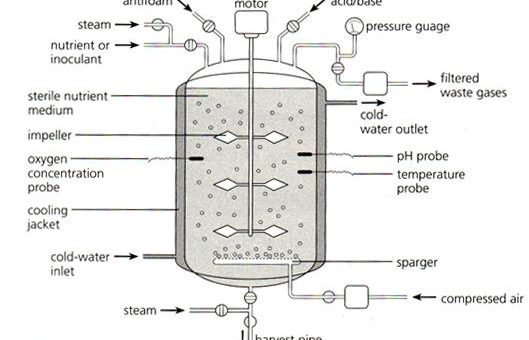

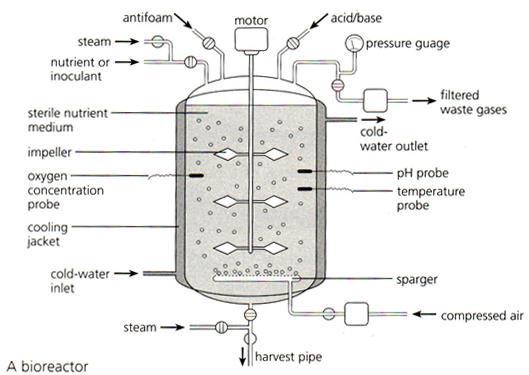

In industrial-scale fermenters, temperature, pH, dissolved oxygen, and agitation are monitored and controlled to ensure optimum cell growth and protein expression conditions. In pharmaceutical manufacturing, an aseptic environment is maintained by sterile-filtration of all process gasses and cell culture media.

When it comes to beer brewing, fermentation is carried out in a mostly oxygen-free environment in which yeast converts the sugars from the barley into ethanol and carbon dioxide. Fermenters are typically sealed from the outside environment with a vent line to allow CO2 to escape the tank and prevent the buildup of pressure. This constant flow of gas out of the vessel helps protects against contamination by other yeast strains and prevents oxygen from the atmosphere from entering the reactor. Since the conversion of sugar to ethanol is an exothermic process, a large-scale beer fermenter generates a considerable amount of heat. Therefore, the temperature of such tanks is controlled by way of a jacket with chilled water or glycol.

To learn more about the brewing process while socializing with friends, make sure to register for the November 30th event hosted by the Boston Area Young Professionals. Members of all experience levels are encouraged to attend. Registration includes one beverage ticket, brewery tour and snacks. (Additional beverages may be purchased at the bar.)

Visit our events page to register. And don’t delay, as the tours will sell out quickly!

0 Comments